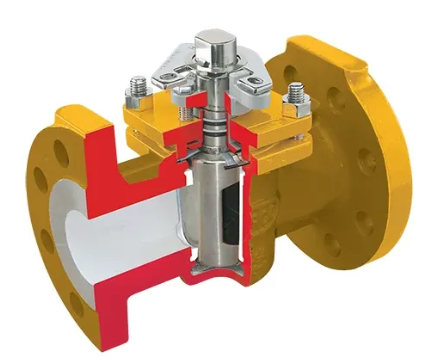

Flowserve has delivered thousands of Durco G4BZ-HF Marathon Sleeveline HF Alkylation valves to refineries worldwide.Designed for high-cycle, low-emissions performance, this non-lubricated plug valve provides exceptional stem sealing reliability.It is a trusted solution for applications where tight shutoff and strict emissions containment are critical for safety.

The Durco G4BZ-HF Marathon valves are listed by Phillips Licensing and approved by UOP Process Division for use in the following applications:

Isomerization

Blending

Light Ends

Gas Plants

Sulfur Plants

Crude Desalting

| Industries | Chemicals: Basic (Organic & Inorganic), Specialty (Fine & Consumer), Petrochemicals, Oil & Gas: Downstream Processing |

| Face-to-Face Standard | ASME B16.10 |

| Guiding | NA |

| Trim | NACE / Severe Service (TSG4), Fire Sealed (G4Z), V-Port Control, High Cycle (G4B Marathon) |

| Valve Size | 1/2” to 20” |

| Pressure Class Standard | ASME B16.34 |

| Design Temperature | -46°C to 288°C |

| Bonnet | Standard Bolted Cover, Top-Entry Design |

| Packing | Live-Loaded, PTFE, Grafoil, Viton, Monel, PFA |

| Pressure Class Range | Class 150, 300 |

| Trim Characteristics | NA - On-Off Service |

| Seating | Metal-to-Metal & Soft Seat (PTFE, Durlon ll, UMPHWE, TFEG, TMHT) |

| End Connections | Flanged (RF, RTJ, and Flat Faced), Threaded (NPT), Socket Weld (SW), Butt Weld (BW) |

| Shut-Off Classification | ANSI FCI 70-2 Class IV |

| Body | Non-Lubricated Plug - ASTM A216 WCB Carbon Steel, ASTM A351 CF8M 316 Stainless Steel, ASTM A351 CD4MCuN 254 SMO, and more ETO. |

| Design Standards | ASME B16.10 — Face-to-Face dimension |

| ASME B16.34 — Steel valves, flanged and buttweld | |

| ASME B16.5 — Flange and flange fitting | |

| ASME B1.20.1 — Screwed ends | |

| API 598 — Valve inspection and testing | |

| Certifications | API 607 – Fire Safe |

| Quality | ISO 9001 |