| Industries | Chemicals: Basic (Organic & Inorganic), Specialty (Fine & Consumer), Petrochemicals, Oil & Gas: Downstream Processing |

| Face-to-Face Standard | ASME B16.10 |

| Guiding | NA |

| Trim | NACE / Severe Service (TSG4), Fire Sealed (G4Z), V-Port Control, High Cycle (G4B Marathon) |

| Valve Size | 1/2” to 20” |

| Pressure Class Standard | ASME B16.34 |

| Design Temperature | -46°C to 288°C |

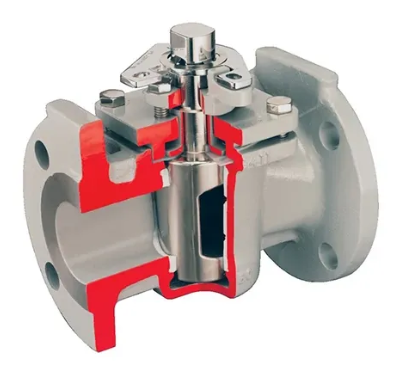

| Bonnet | Standard Bolted Cover, Top-Entry Design |

| Packing | Live-Loaded, PTFE and Fluoropolymer Double Seal, PTFE Diaphragm, PTFE V-Ring, Grafoil for high-temperature applications |

| Pressure Class Range | Class 150, 300 |

| Trim Characteristics | NA - On-Off Service |

| Seating | Metal-to-Metal & Soft Seat (PTFE, Durlon ll, Glass Filled PTFE, UHMWPE, PFA, TMHT) |

| End Connections | Flanged (RF, RTJ, and Flat Faced), Threaded (NPT), Socket Weld (SW), Butt Weld (BW) |

| Shut-Off Classification | ANSI FCI 70-2 Class IV, VI (Soft Seat) |

| Body | Non-Lubricated Plug - ASTM A216 WCB Carbon Steel, ASTM A351 CF8M 316 Stainless Steel, ASTM A351 CD4MCuN 254 SMO, and more ETO. |