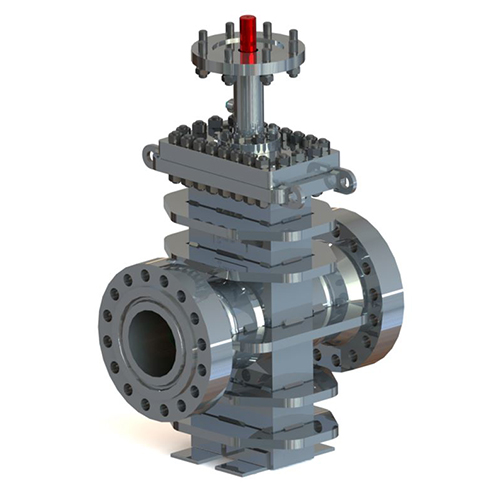

The Valbart TCSGV through conduit slab gate valve is the oil and gas industry's choice for liquid and gas applications requiring reliable, tight shut-off to prevent leakage and minimize losses from process contamination. It is ideal for pipeline applications requiring pigging capability. Its full-bore design features spring-energized seats and a floating slab gate to ensure both low- and high-pressure sealing capabilities. The Valbart TCSGV is manufactured and tested in accordance with API 6D, latest edition. Its design is fully compliant to ASME Section VIII, Division 1. Its design meets API 6D isolation features of block and bleed, double isolation bleed (DIB), double block and bleed, cavity relief, and other requirements commonly specified in the pipeline industry.

| Valve Size | 2" to 42" |

| Pressure Class Standard | ASME B16.34 |

| Pressure Class Range | Class 150, 300, 600, 900, 1500 |

| Body | Fabricated with Engineered Ribs |

| End Connections | Integral Flange, Butt-Weld, Hub |

| Face-to-Face Standard | API 6D, ASME B16.10 |

| Bonnet | Standard, Extended, Cryogenic |

| Packing | PTFE Chevron with Graphite, Fugitive Emission, Live-Loaded, Full Graphite |

| Configuration | Through Conduit Slab |

| Trim | Full Port Piggable and Reduced Bore to API 6D |

| Seat Type | Double Block & Bleed (DBB), Double Isolation & Bleed (DIB-1 & DIB-2) |

| Seating | Metal-to-Metal & Soft |

| Shut-Off Classification | API 6D as per ISO 5208 Rate A, D |

| Certifications | Canadian Registration Number (CRN) |

| Fire-Safe to API 6FA, API 607 | |

| Design Standards | CSA Z245.15 – Steel Valves |

| API 6D – Specification for Pipeline and Piping Valves | |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.47 – Large Diameter Steel Flanges | |

| ASME B16.10 – Face to Face & End Dimensions of Valves | |

| ASME B16.25 – Buttwelding Ends | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding End | |

| ASME SA Materials | |

| ASTM A Materials | |

| Quality | IS0 9001:2008 |

| ATEX QAN | |

| IECEX QAR |