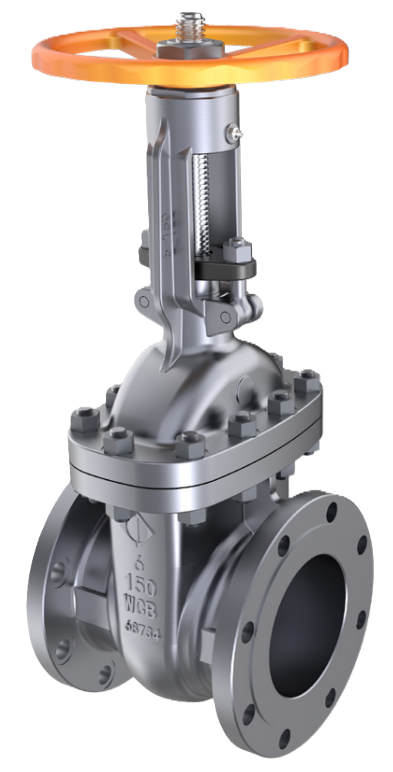

Chaoda’s Cast Steel OS&Y Gate Valves are designed for high-performance critical flow control applications. These valves feature a straight-through, bi-directional flow path that minimizes flow loss and pressure drop, making them ideal for systems where efficiency and reliability are paramount. The flex wedge design ensures consistent sealing even under thermal expansion and pipeline stress, while the standard low-emissions graphite packing and backseat design provide enhanced safety and compliance with environmental regulations. With proven performance in oil/gas refining, chemical processing, power generation, and pulp & paper industries, Chaoda gate valves deliver long-term durability, operational safety, and regulatory compliance in the most demanding environments.

| Valve Size | 2” to 56” |

| Body | One Piece, with Bolted Bonnet |

| Bonnet | Bolted |

| End Connections | Flanged Raised Face & Ring-Type-Joint, Butt Weld |

| Face-to-Face Standard | ASME B16.10 |

| Pressure Class Range | ASME 150 - 2500 |

| Pressure Class Standard | ASME B16.34 |

| Configuration | Full Port |

| Seating | Metal-to-Metal |

| Shut-Off | Tight Shut-Off |

| Certifications | Canadian Registration Number (CRN) |

| Design Standards | API 600 |

| API 603 | |

| API 622 | |

| API 598 | |

| API 624 | |

| API RP 591 | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding Ends | |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.47 – Large Diameter Steel Flanges | |

| ASME B16.25 – Butt Weld End | |

| ASME B16.10 – Face to Face & End Dimensions of Valves | |

| ASME SA Materials | |

| ASME A Materials | |

| Quality | ISO 9001:2015 |

| ISO 17025:2017 |

No manuals available at this time.