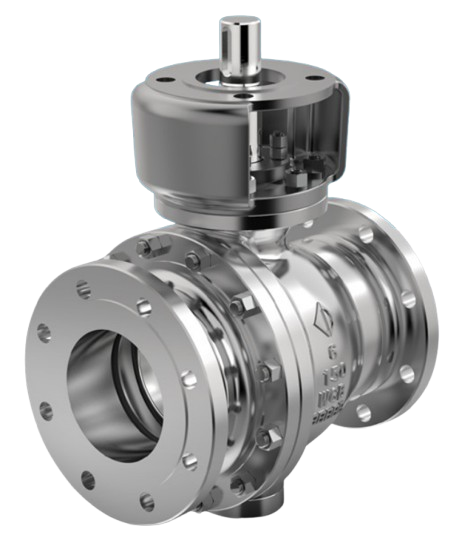

Built for durability and precision, Chaoda’s Metal Seated Trunnion Ball Valve combines advanced surface treatments with a streamlined mechanical design to deliver reliable performance in high-pressure, high-temperature, and abrasive service conditions. The precision-lapped metal seats provide excellent sealing in severe service applications, especially those with abrasive slurries. This makes these valves the most dependable sealing valves available. Ideal for critical isolation, this valve is engineered to meet demanding operational standards with confidence. Minimal moving parts with flawless execution make these trunnion ball valves the perfect choice for severe applications.

| Valve Size | 2” to 24” |

| Body | Three-Piece, Two-Piece |

| Bonnet | Body Integral |

| Configuration | Trunnion Mounted Ball |

| End Connections | Flanged Raised Face & Ring-Type-Joint, Butt Weld |

| Face-to-Face Standard | ASME B16.10 |

| Packing | Graphite, PTFE, other options on request |

| Pressure Class Range | ASME 150 - 2500 |

| Pressure Class Standard | ASME B16.34 |

| Seating | Metal-to-Metal |

| Shut-Off | Tight Shut-Off |

| Trim | Full and Reduced Port |

| Certifications | Canadian Registration Number (CRN) |

| Design Standards | API 608 |

| API 598 | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding Ends | |

| ASME B16.25 – Butt Welding Ends | |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.47 – Large Diameter Steel Flanges | |

| ASME B16.11 – Forged Fittings, Socket-Welding, and Threaded | |

| ASME SA Materials | |

| ASME A Materials | |

| Quality | ISO 9001:2015 |

| ISO 17025:2017 |

No manuals available at this time.