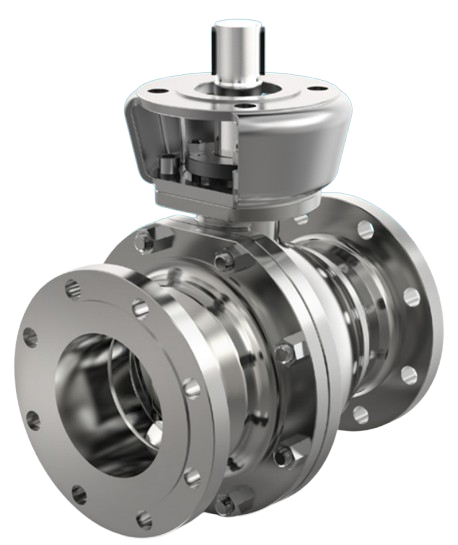

Chaoda’s Metal Seated Floating Ball Valve is engineered for performance in harsh operating conditions. With a compact design and precision-lapped metal seats, it delivers consistent sealing and long-term reliability in abrasive media and elevated temperatures. The minimal moving parts and graphite stem packing enhance durability and reduce maintenance, making it a dependable solution for critical isolation where performance and value are most important. Additionally, full rotational surface lapping of slurry-resistant scraper seats makes this metal seat ball valve the most dependable sealing valve available – at an unparalleled price point.

| Valve Size | ½” to 12” |

| Body | Two-Piece, Three-Piece |

| Bonnet | Body Integral |

| Configuration | Floating Ball |

| End Connections | Flanged Raised Face & Ring-Type-Joint, Butt Weld |

| Face-to-Face Standard | ASME B16.10 |

| Flow Port | Full or Reduced Port |

| Packing | Graphite, PTFE, other options on request |

| Pressure Class Range | ASME 150 - 2500 |

| Pressure Class Standard | ASME B16.34 |

| Seating | Metal-to-Metal |

| Shut-Off | Tight Shut-Off |

| Certifications | Canadian Registration Number (CRN) |

| Design Standards | API 608 |

| API 598 | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding Ends | |

| ASME B16.25 – Butt Welding Ends | |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.47 – Large Diameter Steel Flanges | |

| ASME SA Materials | |

| ASME A Materials | |

| Quality | ISO 9001:2015 |

| ISO 17025:2017 |

No manuals available at this time.