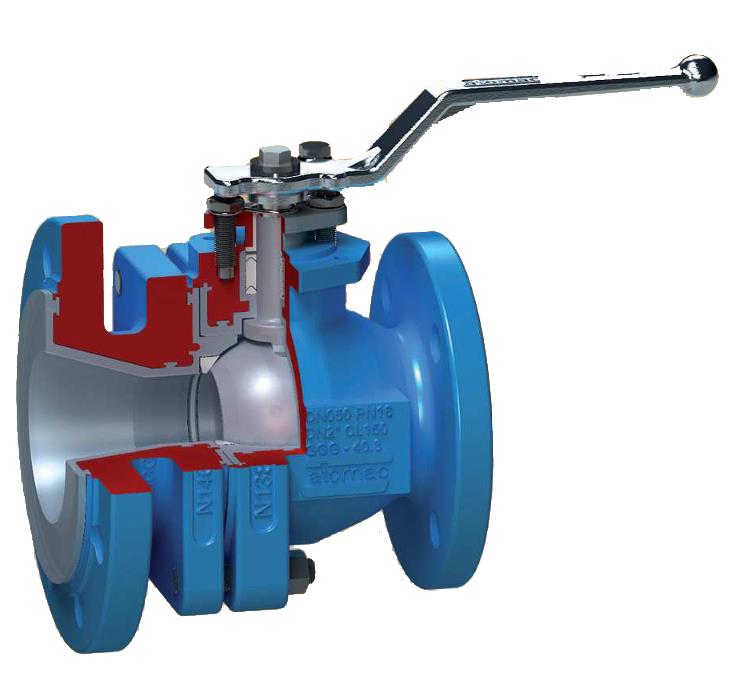

The AKH6, originally designed as a tank drain valve, can also be used to downsize piping by replacing reducing spools. It offers a variety of dimensions per ANSI 150 flange connections. Like other Atomac lined ball valves, it features corrosion-resistant FEP or PFA liners, full ports, anti-blowout stem, anti-static design, and ISO 5211 actuator mounting. Its internal components and spare parts are interchangeable with the AKH2 series, ensuring long-term external leak protection and easy maintenance.

| Operator Options | Non-Locking Wrench, Actuated |

| Face-to-Face Standard | ASME B16.10 |

| Materials | Body: Ductile Iron or CF8M, Stem: SST, Hastelloy C4, PFA, Ball: Alloy Steel / Ductile cCst Iron - EN-JS1049/ASTMA395 / Ceramic Al2O3*, PFA° / FEP, Liner: FEP, PP, or PFA |

| Cv Range | 37.3 to 1388 |

| Valve Size | 1" x 2" to 6" x 8" |

| Design Temperature | -10°C to 200°C |

| Type | Full Port Tank Drain Ball Valve |

| Bonnet | Anti-Blowout Stem |

| Packing | PTFE Chevron or PTFE-graphite |

| Pressure Class Range | ASME B16.34 Class 150 |

| Seating | PTFE, PTFE-glass-reinforced, PTFE-conductive |

| End Connections | Flanged - ASME B16.5 Class 150 |

| Shut-Off Classification | ANSI/FCI 70-2 Class VI (Bubble-tight shutoff) |

| Design Standards | ASME B16.5: Flange dimensions standard |

| DIN EN ISO 5211: Actuator mounting standard | |

| DIN 2501-PN16: Pressure flange standard | |

| CMTR’s on Body and End Plate | |

| Certifications | API 598: Leak test certification |

| Quality | CMTR’s on Body and End Plate |