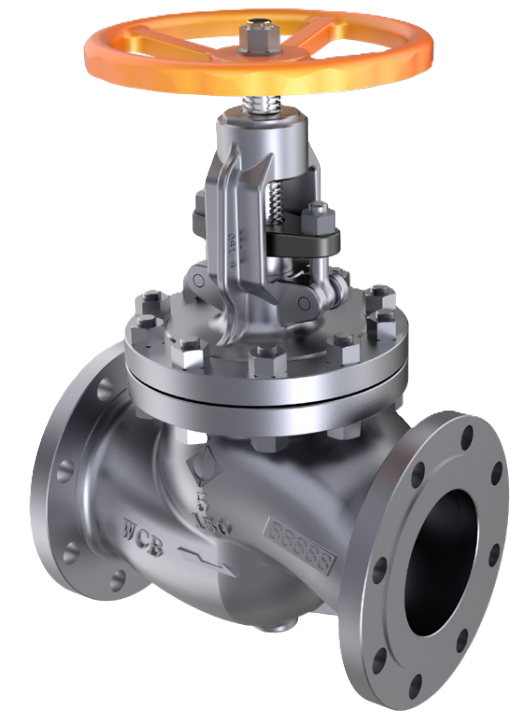

Chaoda Cast Steel Globe Valves are designed for unidirectional flow control in throttling and isolation applications across oil and gas, power generation, and chemical industries. Their cast steel construction, combined with a bolted bonnet and integral forged stem, ensures mechanical integrity and long-term reliability under demanding conditions. Metal-to-metal seating provides superior resistance to wear and erosion, extending service life in high-pressure and high-temperature applications. Cast valves enable the creation of complex shapes, patterns, and sizes that meet application requirements.

| Valve Size | 2” to 16” |

| Body | One piece, with bolted bonnet |

| Bonnet | Bolted |

| End Connections | Flanged Raised Face & Ring-Type-Joint, Butt Weld |

| Face-to-Face Standard | ASME B16.10 |

| Stem | Integral Forged Design |

| Pressure Class Range | ASME 150 - 2500 |

| Pressure Class Standard | ASME B16.34 |

| Seating | Metal-to-Metal |

| Shut-Off | Tight Shut-Off |

| Trim | Stem & Disc Design |

| Certifications | Canadian Registration Number (CRN) |

| Design Standards | API 623 |

| BS 1873 | |

| API 598 | |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.47 – Large Diameter Steel Flanges | |

| ASME B16.25 – Butt Welding Ends | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding Ends | |

| ASME SA Materials | |

| ASME A Materials | |

| Quality | ISO 9001:2015 |

| ISO 17025:2017 |

No manuals available at this time.