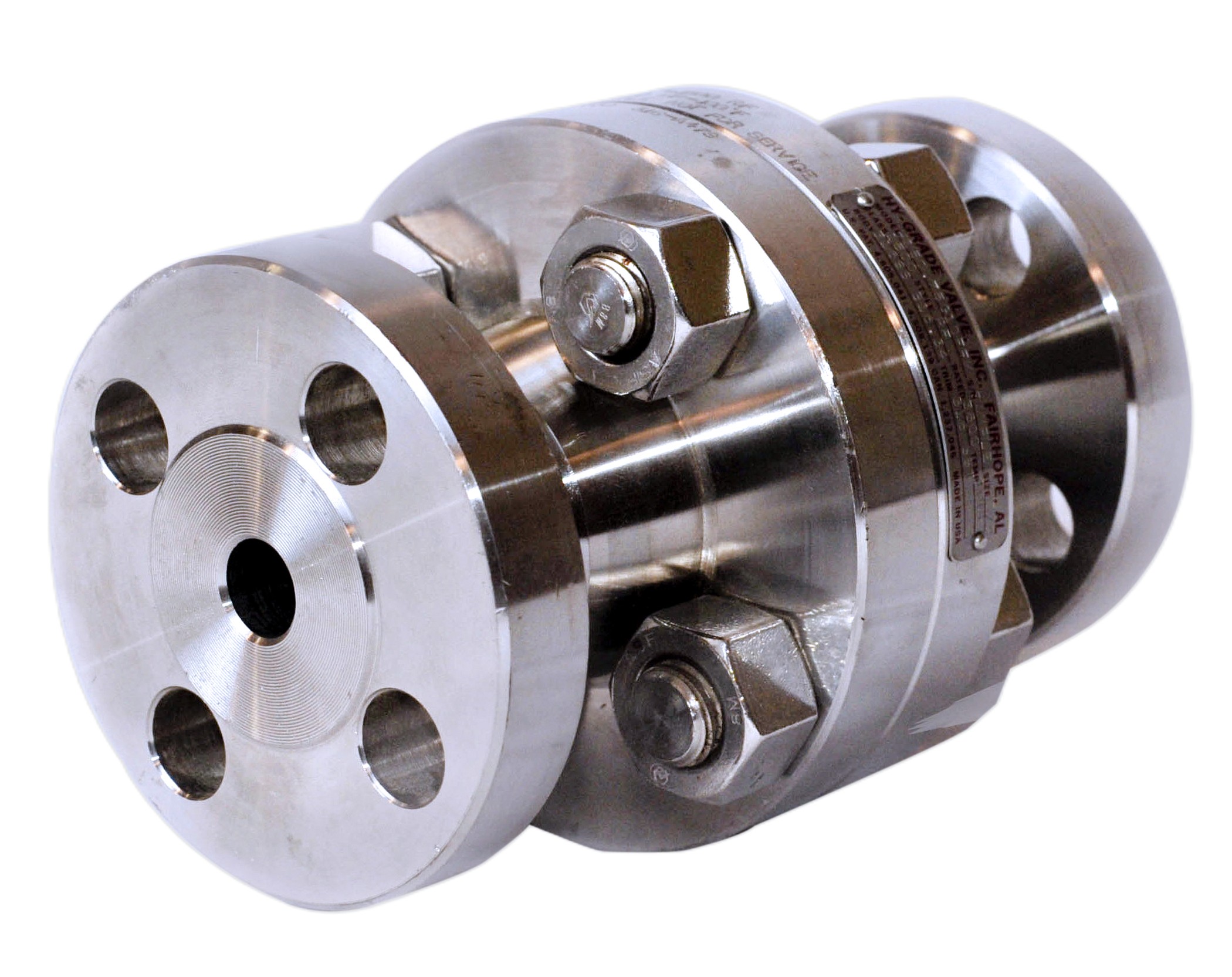

Hy-Grade Series H Flanged End Wafer swing check valves are designed explicitly for flanged, buttwelding and hub ends. The design is the only one to follow a two-piece body design. This design differs from other check valves by incorporating an integrated flapper and pin, providing strength at a critical location. Typical swing check valve designs feature multiple components for the flapper assembly, including bushings, nuts, bolts, and hinge pins. These components wear out over time or come apart, leading to check valve failure.

| Valve Size | 2" to 24" |

| Body | Two-Piece Body |

| Disc | Integrated Flapper-Shaft Design |

| End Connections | Flanged, Buttwelding, and Hub Ends |

| Face-to-Face Standard | ASME B16.10 |

| Media Application | Liquids, Gases |

| Pressure Class Range | ASME 150 - 2500 |

| Pressure Class Standard | ASME B16.34 |

| Seating | Metal-to-Metal & Soft |

| Shut-Off | Tight Shut-Off |

| Type | Flanged End Wafer Swing Check Valve |

| Certifications | Canadian Registration Number (CRN) |

| Design Standards | ASME B16.5 – Pipe Flanges & Flanged Fittings |

| ASME B16.10 – Face to Face & End Dimensions of Valves | |

| API 6FA and 6FD | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding Ends | |

| ASME SA Materials | |

| ASTM A Materials | |

| Quality | ISO 9001:2015 |

No manuals available at this time.