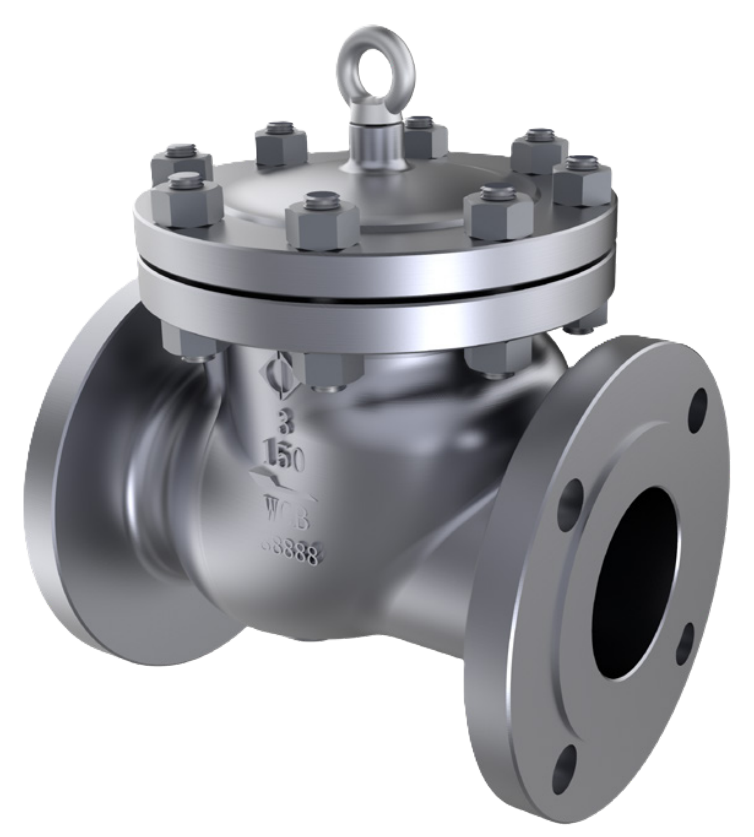

The Chaoda Cast Steel Swing Check Valve is engineered for reliable backflow prevention in demanding industrial applications, including refineries, petrochemical facilities, and chemical processing environments. Manufactured using advanced casting techniques, the valve features a bolted body design, internally retained hinge pins to eliminate external leak paths, and a solid disc with an anti-rotation mechanism for enhanced operational stability. Furthermore, this valve ensures durability and leak-tight performance across liquid and gas media.

| Valve Size | 2” to 36” |

| Body | Bolted |

| Disc | Solid |

| End Connections | Flanged Raised Face & Ring-Type-Joint, Butt Weld |

| Face-to-Face Standard | ASME B16.10 |

| Media Application | Liquid, Gas |

| Pressure Class Range | ASME 150 - 2500 |

| Pressure Class Standard | ASME B16.34 |

| Seating | Metal-to-Metal |

| Type | Swing Check Valve |

| Certifications | Canadian Registration Number (CRN) |

| Design Standards | API 594 |

| API 598 | |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.47 – Large Diameter Steel Flanges | |

| ASME B16.25 – Butt Welding Ends | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding Ends | |

| ASME SA Materials | |

| ASME A Materials | |

| Quality | ISO 9001:2015 |

| ISO 17025:2017 |

No manuals available at this time.