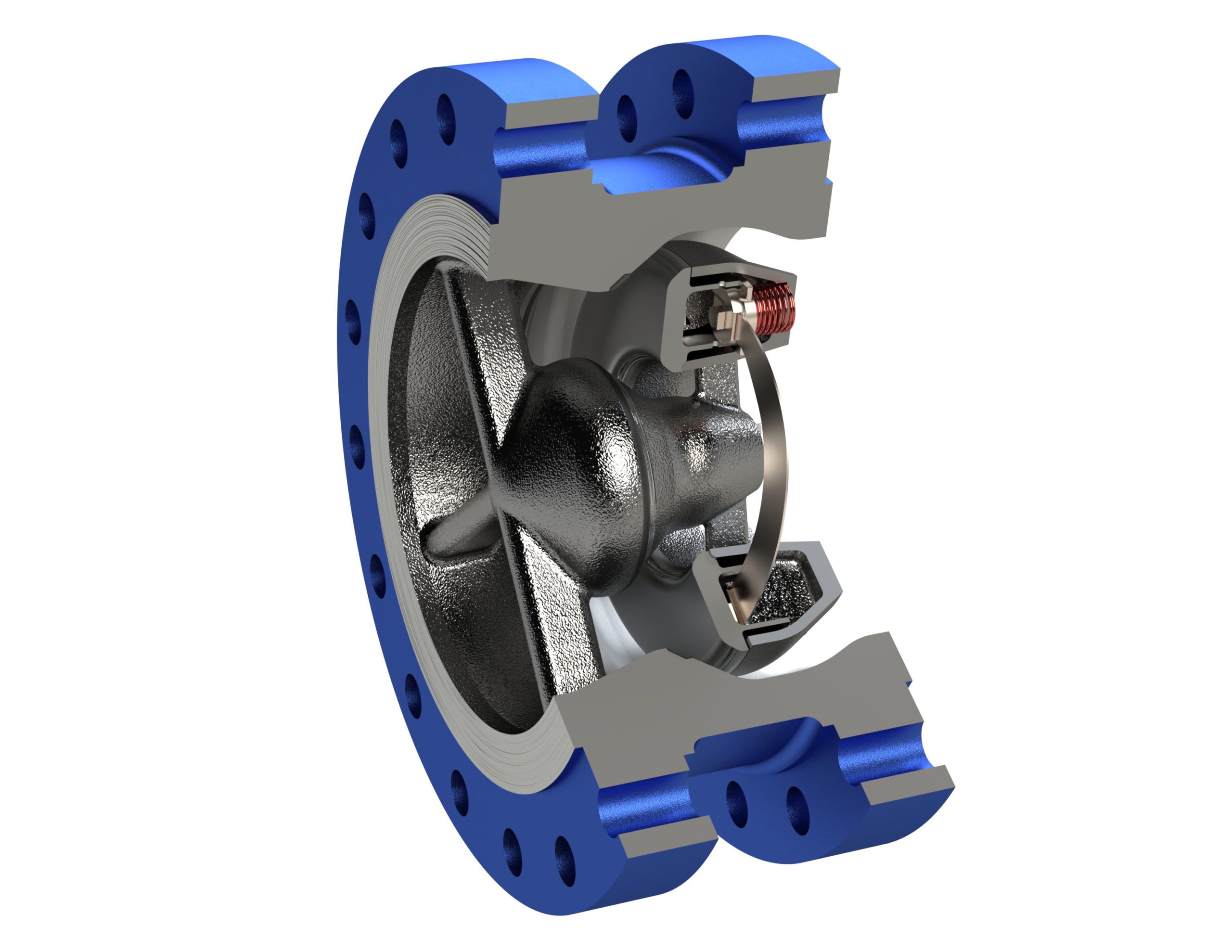

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

| Valve Size | 12" to 88" |

| Pressure Class Standard | ASME B16.34, API 6A |

| Pressure Class Range | Class 150, 300, 600, 900, 1500, 2500, 4500; API 2000, 3000, 5000, 10000, 15000, 20000 |

| Body | One-Piece Body |

| End Connections | Flanged, Hub-End, Butt-Weld, Socket-Weld, Wafer, Lugged |

| Face-to-Face Standard | Manufacturer Compact Standard |

| Disc Type | Ring |

| Guiding | Radial |

| Seating | Metal-to-Metal |

| Flow | Axial |

| Type | Non-Slam Anti-Surge |

| Media Application | Liquids, Gases |

| Shut-Off Classification | API 598, ISO 5208 Rate E |

| Certifications | Canadian Registration Number (CRN) |

| ANSI NSF 61 – Drinking Water System Components – Health Effects | |

| PED 2014/68/EU CE Mark | |

| Design Standards | ASME B16.47 – Large Diameter Steel Flanges |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.9 – Factory-Made Wrought Buttwelding Fittings | |

| ASME B16.10 – Face to Face & End Dimenions of Valves | |

| ASME B16.11 – Forged Fittings, Socket-Welding & Threaded | |

| ASME B16.25 – Buttwelding Ends | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding End | |

| ASME SA Materials | |

| ASTM A Materials | |

| Quality | IS0 9001:2015 |

No manuals available at this time.